3D Printing and Additive Manufacturing: Unlocking Agile Product Development and Digital Transformation for Corporate Innovation

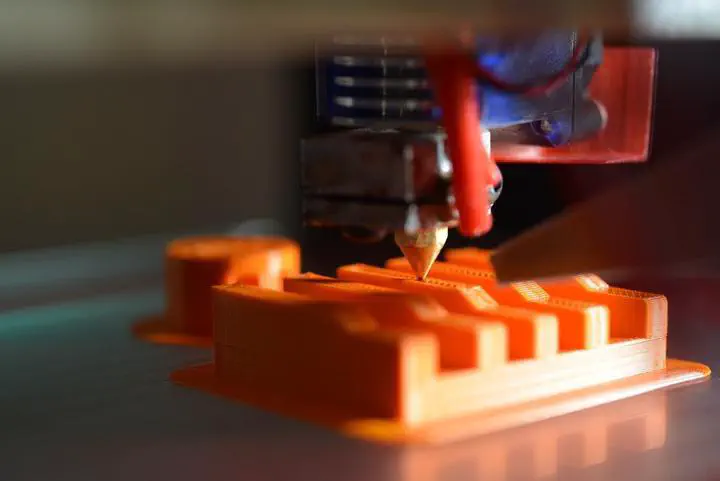

3D printing and additive manufacturing are revolutionizing how companies innovate and develop products. These technologies, also known as “rapid prototyping,” allow for the quick and efficient creation of physical objects, reducing the time and cost associated with traditional manufacturing methods.

The ability to rapidly prototype new ideas and iterate on designs has made 3D printing and additive manufacturing essential for corporate innovation. With these technologies, companies can quickly test new product concepts, gather customer feedback, and iterate on designs in a fraction of the time it would take using traditional manufacturing methods. This newfound ability unlocks three key outcomes.

Agile Product Development

This agility in product development has enabled companies to be more responsive to market changes and customer needs, leading to more successful products and increased competitiveness. In addition, 3D printing and additive manufacturing have allowed for more product customization and personalization, further differentiating companies from their competitors.

Low-cost Prototyping and Custom Parts

Another significant benefit of 3D printing and additive manufacturing is the ability to produce small quantities of products at a relatively low cost. This has enabled companies to efficiently produce custom parts and prototypes, which can be used for testing, evaluation, and demonstration purposes. This has also allowed companies to test new products before investing in mass production, reducing the risk of product failure.

Digital Transformation

Digital transformation is also another way 3D printing and additive manufacturing can be used to drive innovation. With the ability to quickly and easily produce physical objects from digital designs, companies can now use digital twin technologies to create digital representations of their products. This allows them to simulate and test products in a virtual environment, reducing the need for physical prototypes and shortening the product development cycle.

In summary, 3D printing and additive manufacturing are potent tools that can enable agile product development and digital transformation for corporate innovation. These technologies can drive innovation and competitiveness by allowing companies to quickly prototype new ideas, gather customer feedback, and iterate on designs. Moreover, the ability to produce small quantities of products at a relatively low cost and the possibility of digital twin technologies make them even more valuable for companies.